Pumps Expert System

Introduction

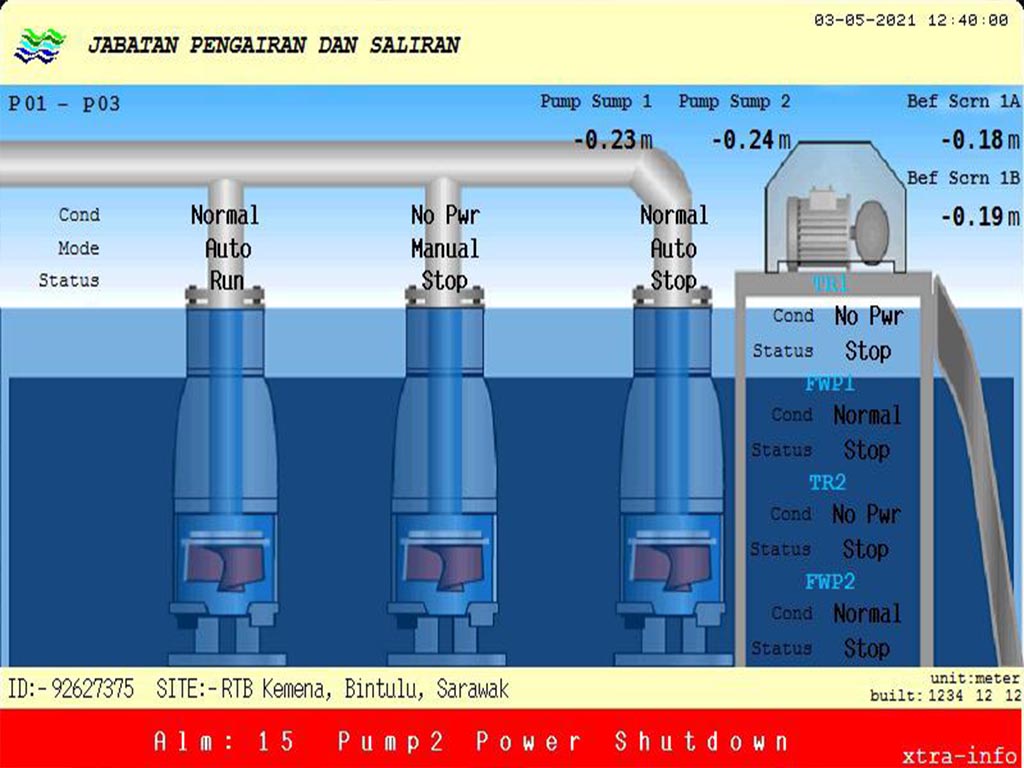

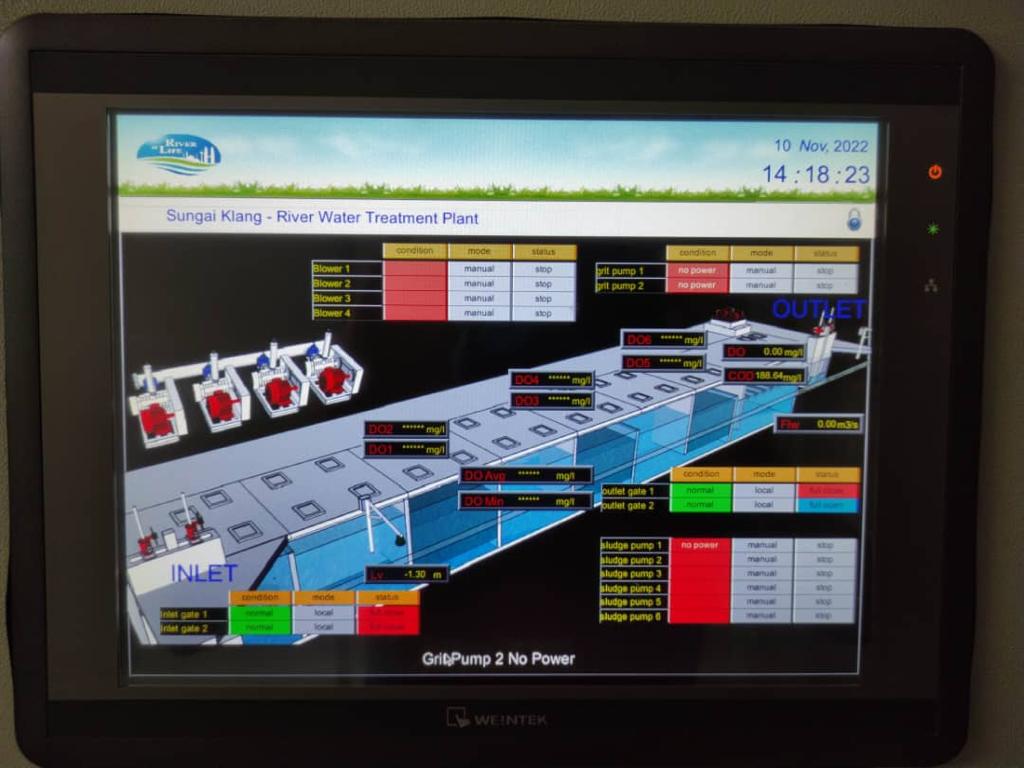

Pump automation and SCADA (Supervisory Control and Data Acquisition) systems are used to manage, control, and monitor pump stations and associated equipment in various industries, such as water distribution, wastewater management, industrial processes, and more. These systems combine automation, real-time data collection, remote control, and visualization to ensure efficient pump operation and effective management. Here's an overview of their key components and functions:

Key Features

Pump Control and Automation: Pump automation systems automate the operation of pumps based on predefined parameters such as flow rates, pressure levels, tank levels, and schedules. This eliminates the need for constant manual intervention and optimizes pump performance.

Sensor Integration: These systems incorporate sensors to monitor parameters like flow rates, pressure, tank levels, temperature, and more. Sensors provide real-time data that informs pump operation and system management.

Data Acquisition: SCADA systems collect data from sensors and devices located in pump stations. This data is processed, aggregated, and stored for analysis, visualization, and decision-making.

Alarms and Alerts: Pump automation and SCADA systems can generate alarms and alerts when abnormal conditions or failures are detected, such as pump failures, low tank levels, or system malfunctions.

Historical Data Storage:These systems store historical data, allowing operators to analyze trends, patterns, and performance over time for maintenance planning and optimization.

Remote Access: Operators can remotely control pump operations, change setpoints, and adjust parameters from a central control room or other remote locations.

Integration with Navigation Systems: SCADA systems can integrate with other systems, such as maintenance management software, billing systems, and data analytics tools, to streamline operations and data utilization.

Maintenance Planning: Based on historical data and performance metrics, these systems can assist in planning preventive maintenance schedules and identifying maintenance needs.